More like, who’s brewing? It’s been 2.5 years since we started this construction project and 2.5 years since we last brewed beer. I’m happy to report, we are back in business!

Our new setup is awesome!

We moved our stand into the shop. We’ve always brewed outside in the past, so we’re pretty excited to be indoors, operating in a controlled environment. Gone are the days of huddling around the boiling pot for warmth in the winter.

Brewing in the summer wasn’t a dream either. The winds blew yard debris into the pots, spiders occasionally dropped into the boil, frogs took refuge in the stand, and worst of all yellow jackets nested in the valves.

We’ve made a number of upgrades. Sam plumbed a propane line into the building which feeds directly to the burners.

I don’t know how many times we ran out of propane mid-brew, and Sam had to drive to a gas station to refill a tank. In the future, we will have an electric heating option too.

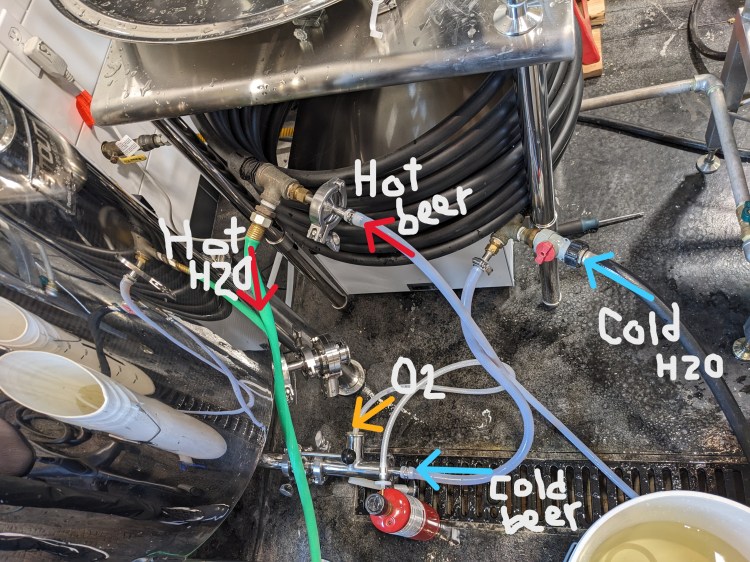

We also have hot and cold water lines coming up through the floor in the brewing area, which will make filling the pots and cleaning them more convenient. The pipes aren’t hooked up to anything yet, but next time we’ll unpack the faucet and have this set up.

We upgraded the stand for our heat exchanger. It not only looks nice, but we won’t have to carry the 50lb slinky around or worry about it freezing outside (that happened once).

And my favorite new addition…

A shiny conical fermenter! Instead of filling 4-5 cumbersome carboys, we can pump the whole batch of beer into the fermenter. The fermenter not only replaced the carboys but also the lagerator fridge. (See the old setup below.)

Some of you may think that we chose not to brew for two years because we were too busy. It was actually the lagerator that was the ultimate demise to our brewing operation. We had just brewed 25 gallons of a refreshing IPA to get us through the first summer of construction in 2021. Sam checked on the beer one night to see if it was ready, and we went to retrieve our first keg a few days later. On the drive over, we heard devastating news on the radio that many local cherry orchards lost their entire crop due to an unexpected spring freeze. Little did we know we were about to discover something more devastating. We opened the lagerator door to see melted plastic everywhere, charred insulation, and deformed plastic carboys full of an undrinkable dark liquid. Apparently the temperature sensor slipped out when Sam shut the door, and the lagerator nearly set itself on fire trying to combat the freezing temperature that the sensor was reading.

We had to throw everything away, including the lagerator. It’s impossible for us to have a meltdown now! Our new fermenter has a cooling jacket between two of its steel walls. This tiny glycol chiller circulates the refrigerant through the cooling jacket.

Brew day went off without a hitch! We brewed a little under 20 gallons of Black IPA.

The fermenter really simplified things at the end. Our old method involved oxygenating each carboy once it was filled. Then we measured out the yeast and added some to each carboy, being careful not to contaminate anything. Sam had a designated stool for this step because it took so long.

Our new system required 4 less hands and no broken backs! After pumping the wort (beer) through the heat exchanger, the whole batch of cooled wort filled the tank along with some oxygen (to help the yeast do its thing). Then we dumped the yeast into the top.

Two weeks later we drained some of the sediment and collected yeast off the bottom. This was quite messy. We didn’t release enough pressure before opening the valve, and brown sludge came gushing out everywhere.

We let some pressure out the top, and Sam filled a glass mason jar with yeast (to reuse next time). Bang! The wet glass jar slipped through his hands and exploded on the floor! We finally made it past the mess, collected a new jar of yeast, and added dry hops to the tank.

On the plus side, clean up was a breeze! We got excellent use out of the floor drain. I don’t think any glass shards even made it through the grate. We hosed down the tiled wall and mopped the rest of the mess away from the tile base boards.

Tiling the brewing area was a last minute decision we made once our tile guy finished the kitchen backsplash. I think it was a great decision! He tiled around the brewing sink as well.

About two weeks later, we “crash cooled” the beer to get the floating sediments to settle at the bottom. This helps to clarify beer without using a filter. Well… our new setup wasn’t as foolproof as we thought. The temperature probe wasn’t in the beer all the way, and we froze our beer. Not good.

We carbonated the beer while it was in the fermenter (another great feature) and filled our first keg.

Oh yeah, we got a new kegerator too! Our old converted chest freezer was so gross, we couldn’t even give it away to someone to store frozen fish in. The new one has a cabinet door on the front, which tremendously decreases the risk of shoulder injury when loading a keg in. Plus, it has two tap towers and can accommodate more kegs. We only have one tower set up now, but just wait.

The beer is tasty, but it unfortunately lost a lot of aroma from the freeze. We are experimenting with hop extracts to jazz it up a little.

Overall, we’re very happy with the new setup. We learned a lot of lessons and are excited to brew again. Cheers!