We finally tore down the wall and built ourselves a door!

As you may recall, we built the first half of the shop door in January… (blog part 1)

The door project was on the back burner until August when we resumed working on it. First we had to make room to build the second half. We flipped the first half of the door over and cleared some space.

Flipping the door over was a challenge. We lifted one end with the crane and used the attic hoist to assist with the flip. Our red rolling stands also came in handy.

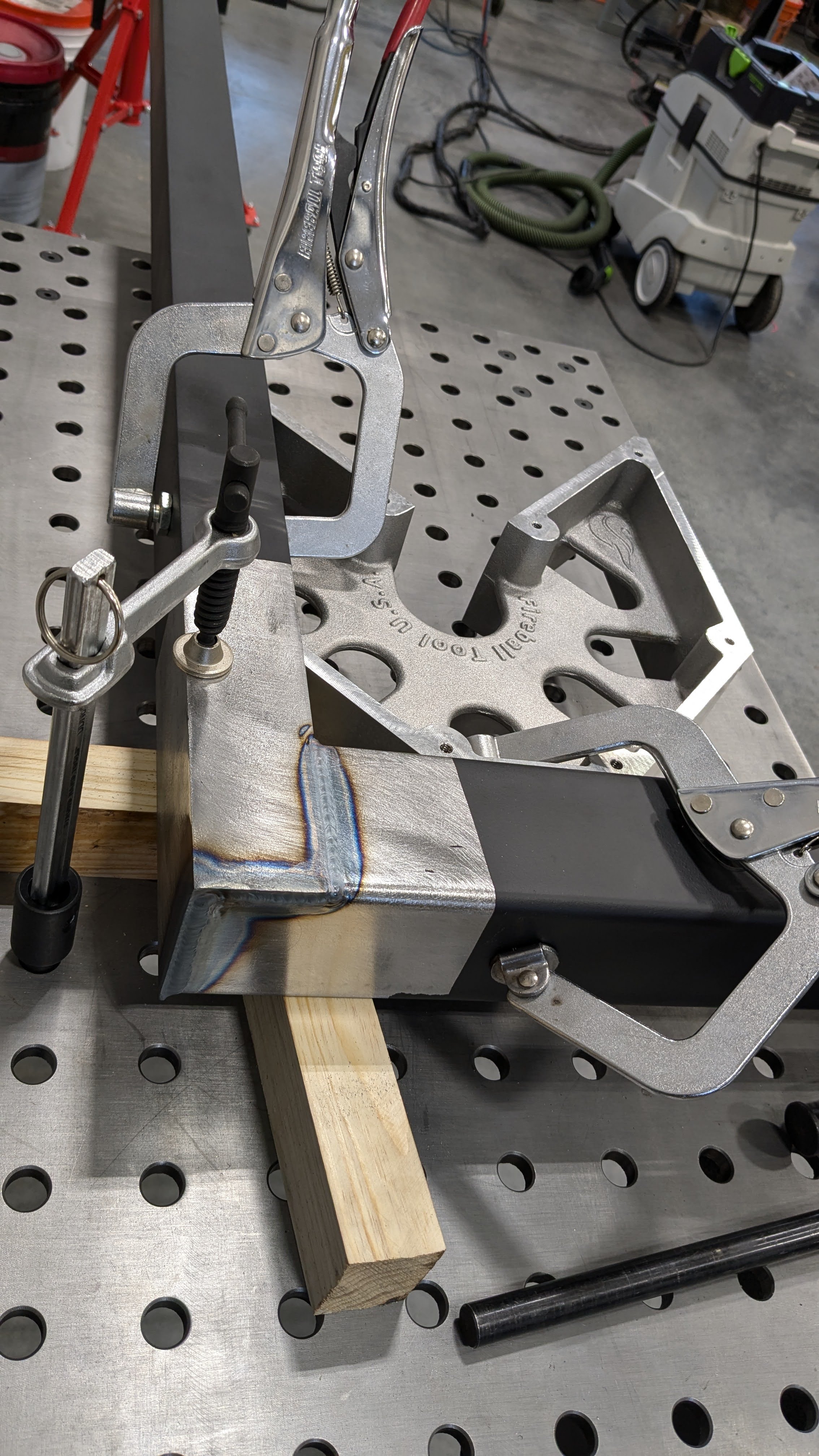

Sam pinned the two door halves together before assembling the second frame. This would ensure the two halves would align post-welding.

Similar to the lower door half, Sam welded the four corners together and attached some parts he machined.

I should take a moment to comment on Sam’s new welding setup. First off, he got a new welder that is better at handling thicker material. Secondly, he got a new helmet and a welding vacuum. The vacuum makes Sam look like a ridiculous scuba diver wearing a fanny pack, plus he has one more thing to cart around. But, it sucks the welding fumes and blows fresh air into the helmet! The helmet itself is the star of the show though. Never in the last 15 years have I heard Sam talk about one thing so much. Apparently it is like seeing in color for the first time! Ask him about it (if you have 20 minutes). You might be convinced to buy one even if you don’t know a thing about welding.

Back to the door… The other steps didn’t get any more fun the second time around. We painted, added wood stiffeners, drilled a hundred holes in the steel frame, and stuffed it with foam. Douglas helped rivet the white panels on. All of this went pretty quickly.

Next, we covered the back of the doors (the side facing outside) with a peel and stick waterproofing rubber. The rolls of material weighed about 100 lbs each. We cut some strips and managed to stick it down without too many bubbles. Then we taped the edges. We were very thorough in the waterproofing process because we probably won’t be putting the siding on the door any time soon.

Shop space was getting tight again. Sam and I shuffled more things with the crane, clearing a space to flip the second door half over. By the end of all this, we were quite comfortable flipping the 600 lb door halves over.

In a few more hours, the upper door half was complete! There was still a lot of preparation to be done for the installation. Sam made some mounting brackets and attached the lift to the wall.

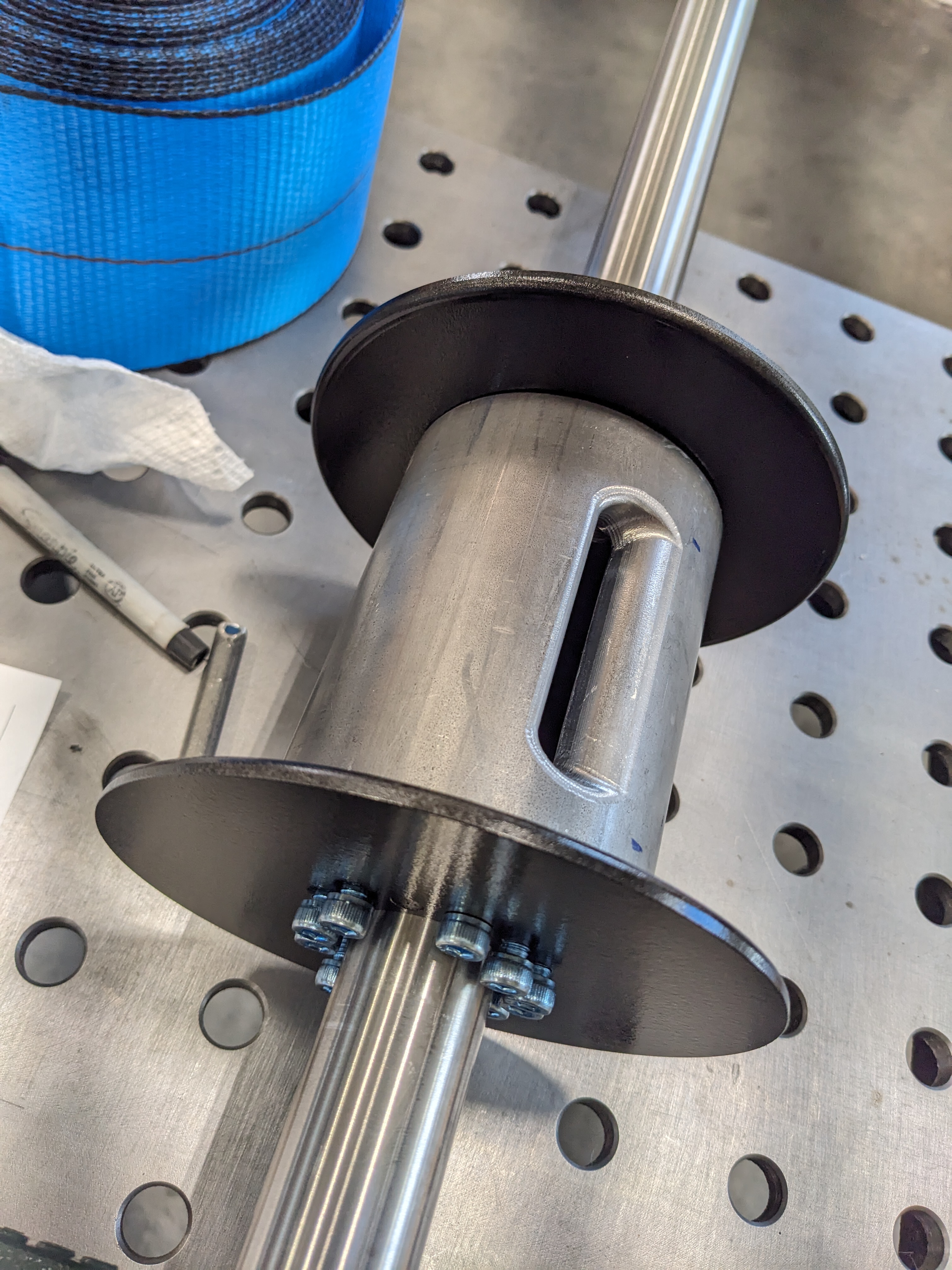

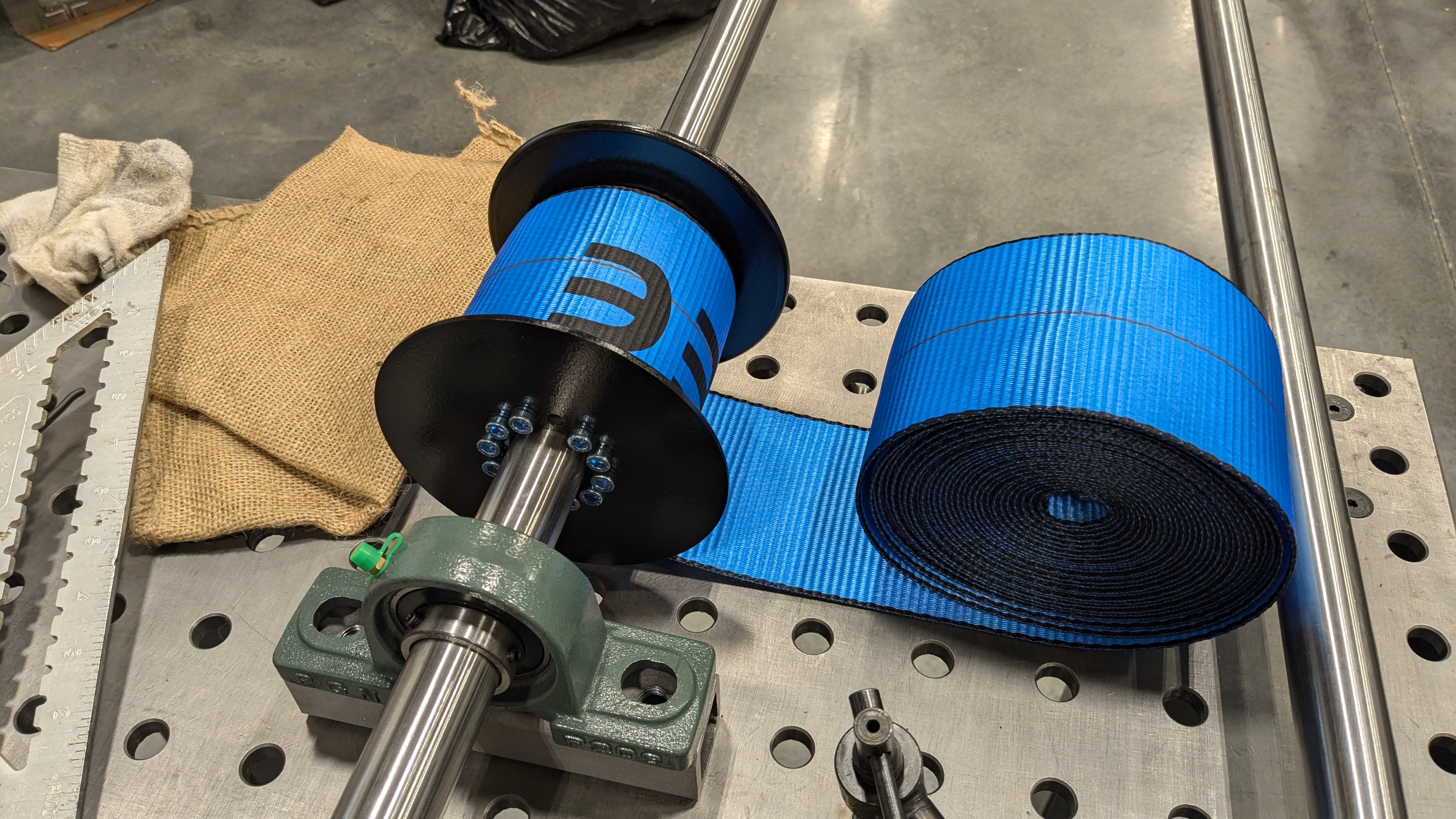

Then he machined the giant shaft.

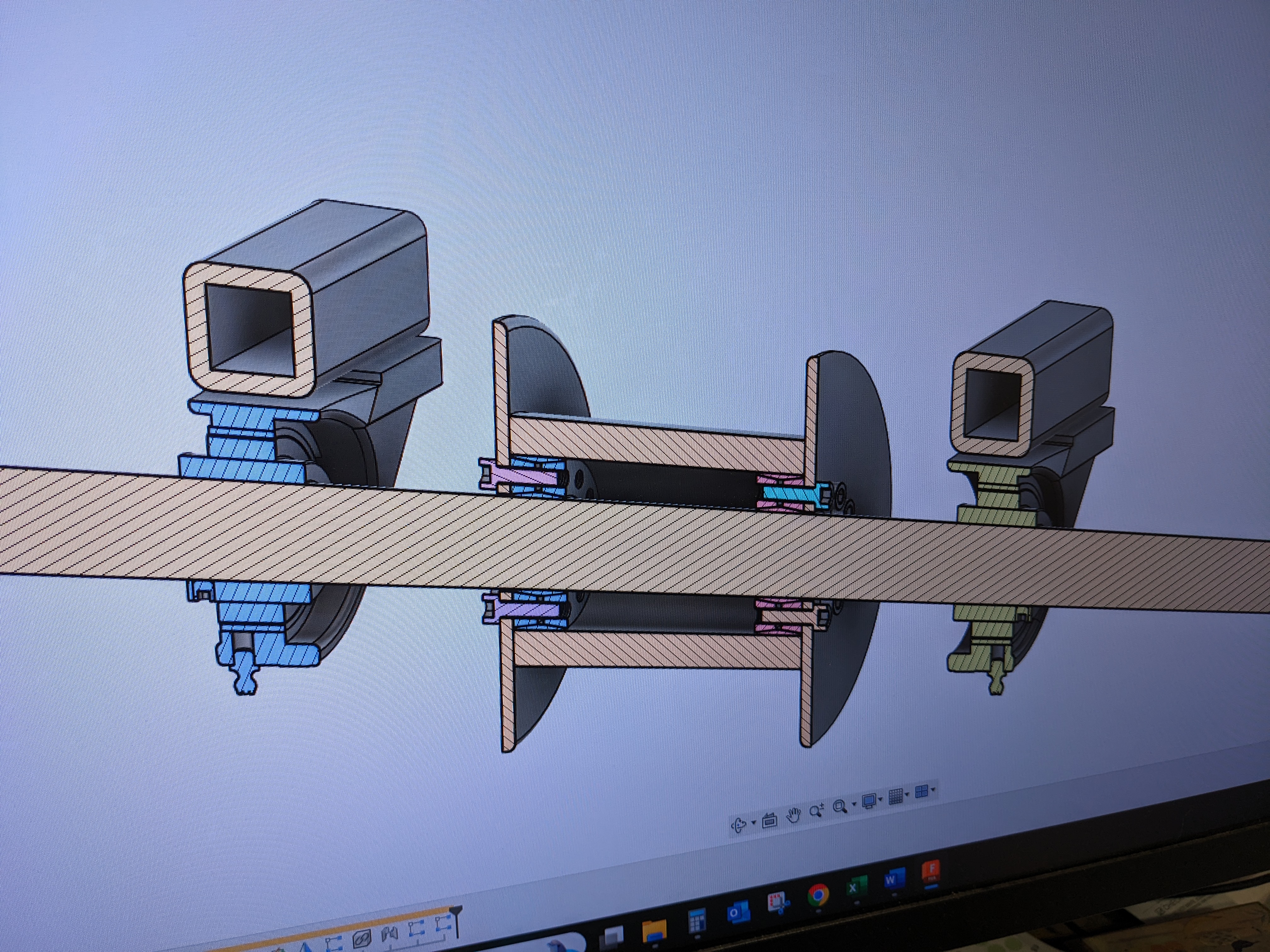

Sam designed all the hinges and lifting mechanisms and machined some parts for a few days.

The cylindrical parts that the lifting straps wind around are really cool.

Once all the parts were made, Sam drilled some more holes in the building and welded the bearing mounts that hold the shaft. Sam usually welds alone, but this was a unique three-person welding job! I craned the welder around and made sure nothing on the ground caught fire. Douglas was outside in the big scissor lift, holding a windshield for Sam. The wind really wasn’t cooperating that day, but Sam got the job done!

Then they mounted the shaft and bearings. The rod alone is very heavy, so I didn’t participate in the installation. It appeared to turn easily, so Sam must have done a good job.

Everything was in place. Sam even made brackets to fork lift the door.

We rented a 8000 lb telehandler and recruited Douglas and Jackson for the big installation!

Sam and I got up early to take down the great wall! I discovered a bat sleeping between the wood and the plastic in the shop!

Sam took the cutie out to safety before the wall came down.

First up was the lower half of the door, which was inconveniently furthest from outside.

We got it out and safely set it down. Then we did another choreographed dance with the crane and the attic hoist, handing the upper half of the door onto the forks.

Clearances were tight. Once the second half was outside too, we all exhaled for the first time in thirty minutes.

We mated the two halves and pounded the pins in.

The guys greased up the hinges.

Then they put the seal in the bottom of the door. It was very difficult to shove the seal into the tracks, so Sam joined in. The seal kept popping out, plus it was getting more difficult to overcome the friction to push, so I joined in too. This minor step somehow required the most physical exertion. We finally got it in.

Then it was time for another scary maneuver – lifting the entire door!

Sam slowly lifted the assembly and got it in the air, unscathed. We all took our second deep breath of the morning.

Then Sam carefully walked the door into place. This is where the telehandler really shines – it self-levels, tilts side to side, crab walks for a lateral translation, and this tele in particular had a vertical axis pivot. Sam used every one of these features to line the door up.

Jackson joined Douglas in the attic to “receive” the door. They made sure the forks didn’t hit anything while directing Sam to line up the hinge points. The forks fit through a small gap above the attic floor which will be covered by the door seal flap. Sam was extremely careful, and we all made a great team guiding him in.

Once in place, Jackson and Douglas locked everything in position and tightened the hinge bolts. There is a giant piano hinge in the center and smaller hinges on the corners.

The door fit perfectly, and the installation couldn’t have gone any smoother! We were done by lunchtime!

We opened the door with the crane to check that the rollers on the sides tracked well and that the lower seal behaved properly. We have a few steps to go before the door is fully operable, but at least it’s in! We won’t have a leaky wall this winter!

In celebration, Sam and I kegged our fresh hop IPA. We went to Yakima valley during the annual hop harvest and collected a bounty of wet and dry hops!

Cheers!