Sam got a “new” CNC mill! It’s a Doosan DNM 650 II. It has a 24 hp spindle that can run at 12,000 rpm vs. 5000 rpm on our old mill. The rapid speed on the table is 1200 inches per minute vs. 200. It’s quite an upgrade!

Sam had it trucked from Colorado. The mill weighs about 19,000 lbs, which is way too heavy for any of our machines to lift. Sam had to work out some logistics to get it into the shop. He had it delivered to our awesome neighbors at the ranch.

To unload the mill, the Kreps borrowed a big forklift with an 18,000 lb lifting capacity.

Then Sam, Kevin, and Kris paraded a few miles up the road to our place.

Sam tried to finish the giant garage door before its arrival, but unfortunately ran into some setbacks. Since it wasn’t operable, we had to squeeze the mill in through the smaller door.

The forklift could barely lift the mill and was apparently very jerky to maneuver. Kris carefully approached the garage door, but the front wheels started to lift as he drove up the ramp. We put dollies under the front of the mill to take some load off. Then we watched with baited breath as the mill barely cleared the garage door opening.

It was in! The forklift was too heavy to drive into the garage, so we set the mill on dollies. One of the big star-shaped dollies immediately bent! Luckily Sam had extra rollers. The guys pushed the mill the final distance across the floor.

The mill placement did not pass the cat inspection. It was a little too close to their feeder and lounge area. Unfortunately the rollers were perpendicular to the direction Buster wanted to move it. Hours later, Sam and Kevin moved it a couple feet down. They set it on big plates to distribute the load. Buster approved of its new location. Smokey wishes the machine was gone.

The mill came with a conveyor that carries the chips out and deposits them into a trash can. After cleaning out years worth of stinky sludge, Sam and Kevin got the conveyor in place.

Although the “new” mill was state of the art in 2014, the controls feel like they’re from 1999. Getting it to run wasn’t as straight forward as our smaller mill. Sam couldn’t find enough useful information online and had to resort to the multi-volume library of manuals that came with the mill. Most were in English but they may as well have been written in Korean. Sam persevered. A few days later, after some more reading and internet browsing, Sam got it to run!

Buster is mesmerized by the automatic tool changer (another feature that the old mill was lacking).

However, he hides out with Smokey when a noisy job is running.

Sam is still learning, but he already put over 50 hours of run time on it making parts for a customer.

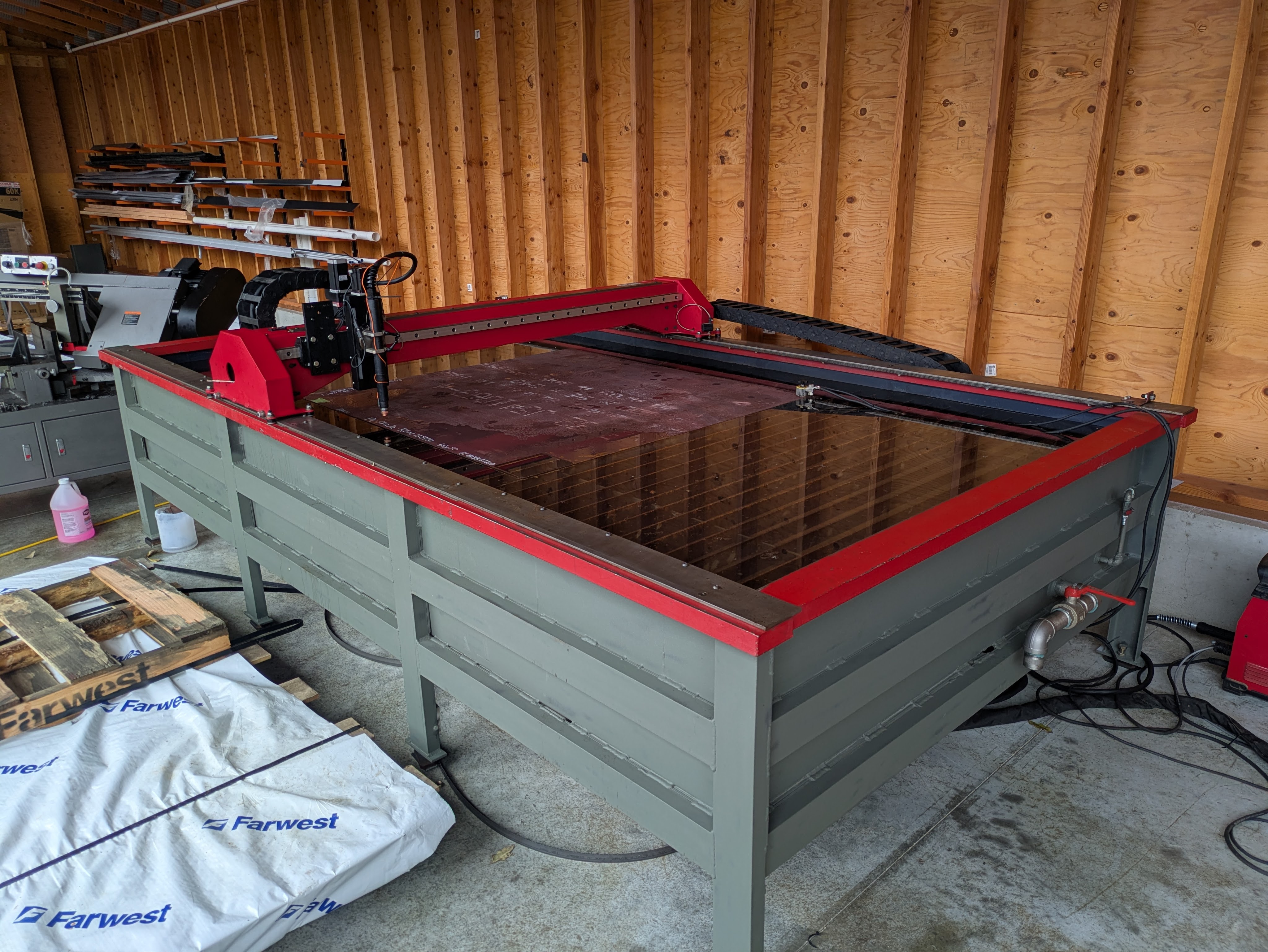

Sam got a few other machines too. As soon as the “shed” was complete, Sam loaded it up and purchased a plasma table.

He tested it by cutting out some cat hooks.

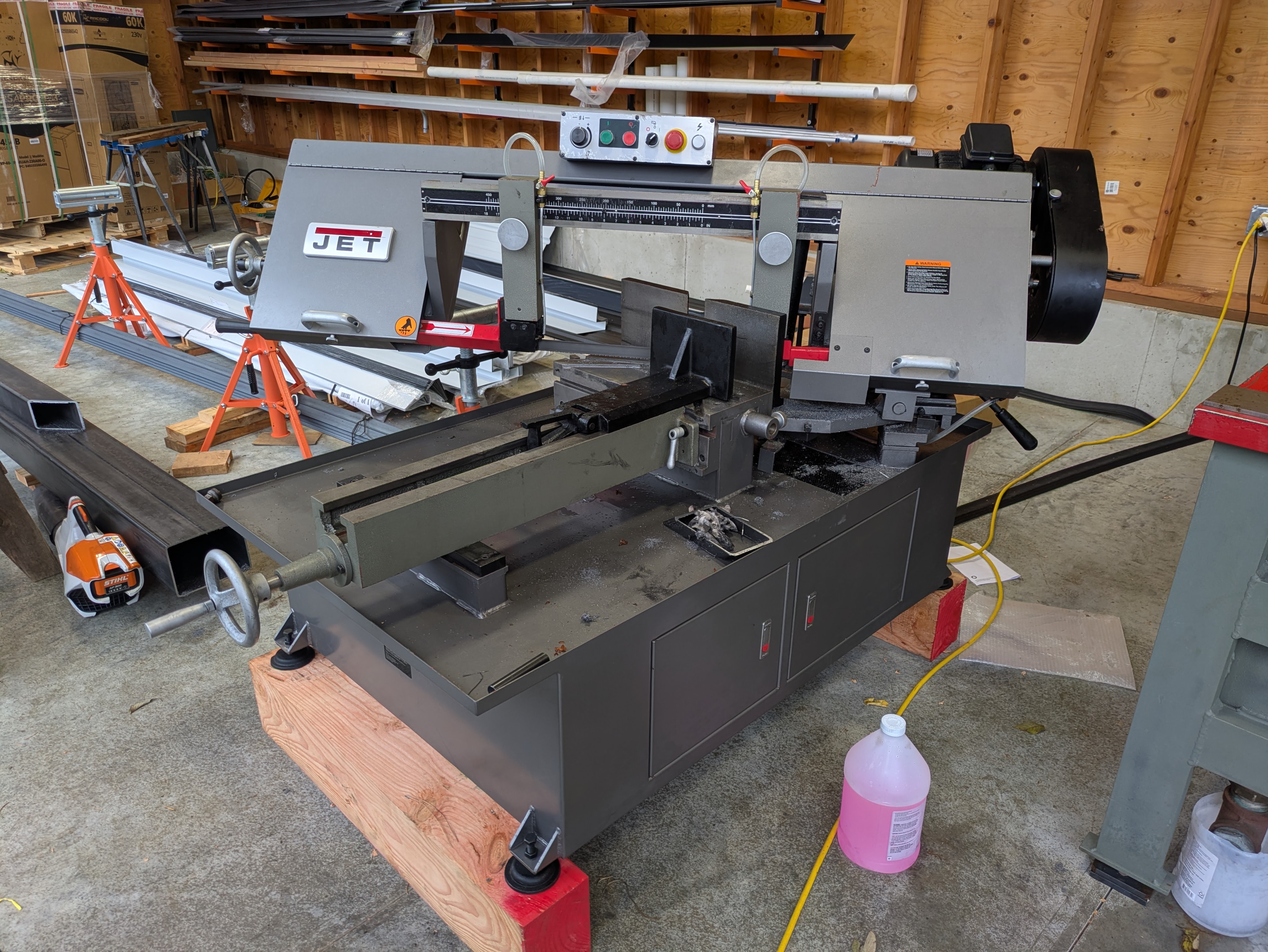

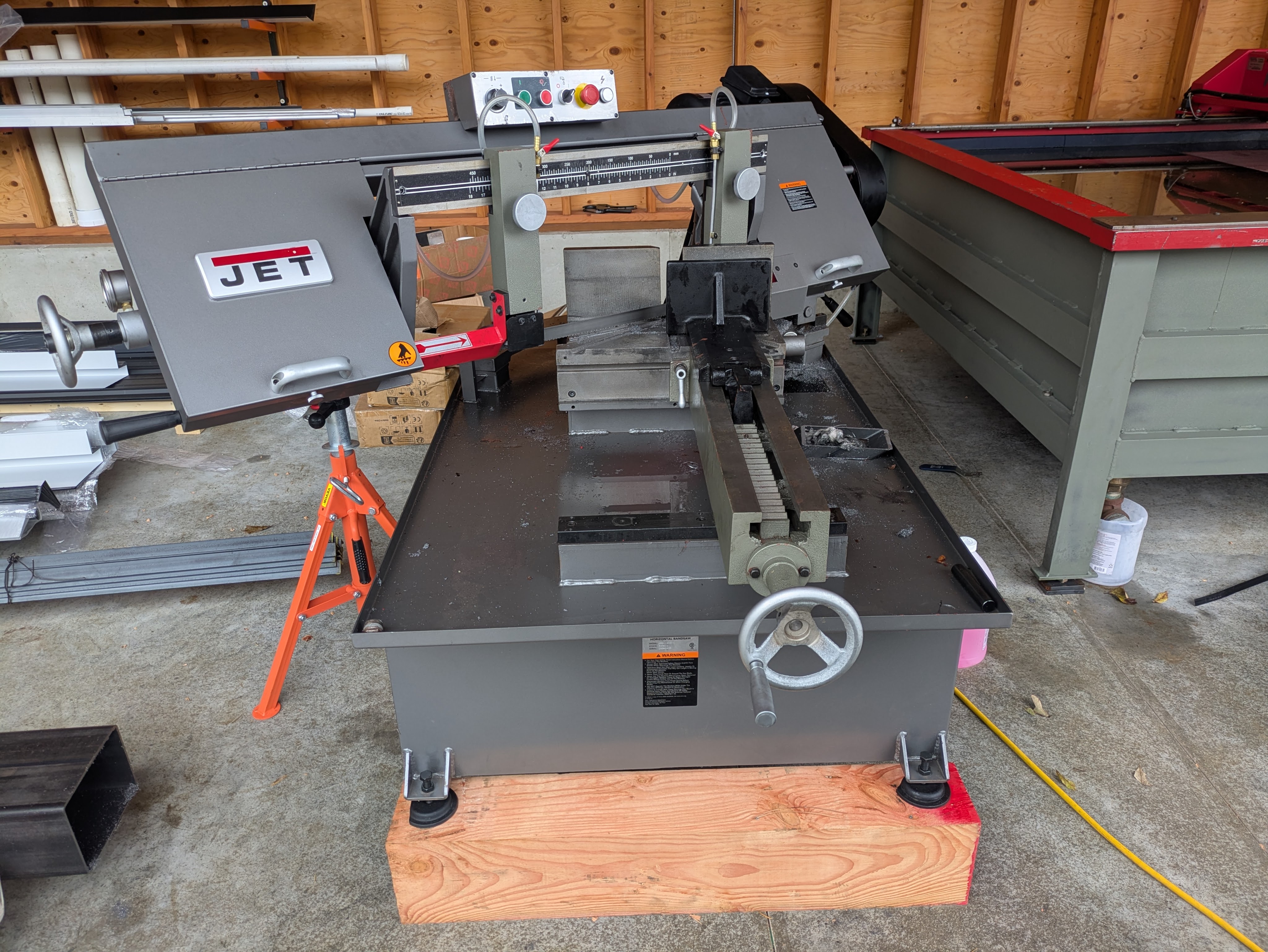

He also got a band saw that can cut angles.

Since the shed doesn’t have doors, it’s the perfect home for all of the messy metal cutting tools.

At least the new garage isn’t full yet. We’re running out of space already!