That’s what I said to Sam as I approached the third trimester. Our mattress had been on the floor since we moved in. I was never fond of the teenage boy’s room look, and getting up was becoming more difficult each day. Sam offered to make a bed for me, but there was one problem- I didn’t design it yet.

I had worked on a wooden bed design off and on for a year. I got as far as making a CAD model, picking out the wood, and a making a cut list. It was going to be a huge project. Simply preparing the rough cut slabs of eucalyptus that we’ve been schlepping around from California would be a big undertaking. Luckily we put the project off for so long, that I no longer wanted a eucalyptus bed. I wanted a metal bed to balance the existing wood furniture in our bedroom. This was music to Sam’s ears, as we have learned that metalworking is his bread and butter, and carpentry is his coleslaw with extra mayo.

Sam was about to place a metal order for another project, so I had to act fast. In typical fashion I focused on the big picture and aesthetic look; whereas Sam wanted to know the details of how all the parts would be assembled. We came up with a plan together and ordered the steel.

Most steel tubes come in 20′ segments, but one was 24′ long! It weighed a ton!

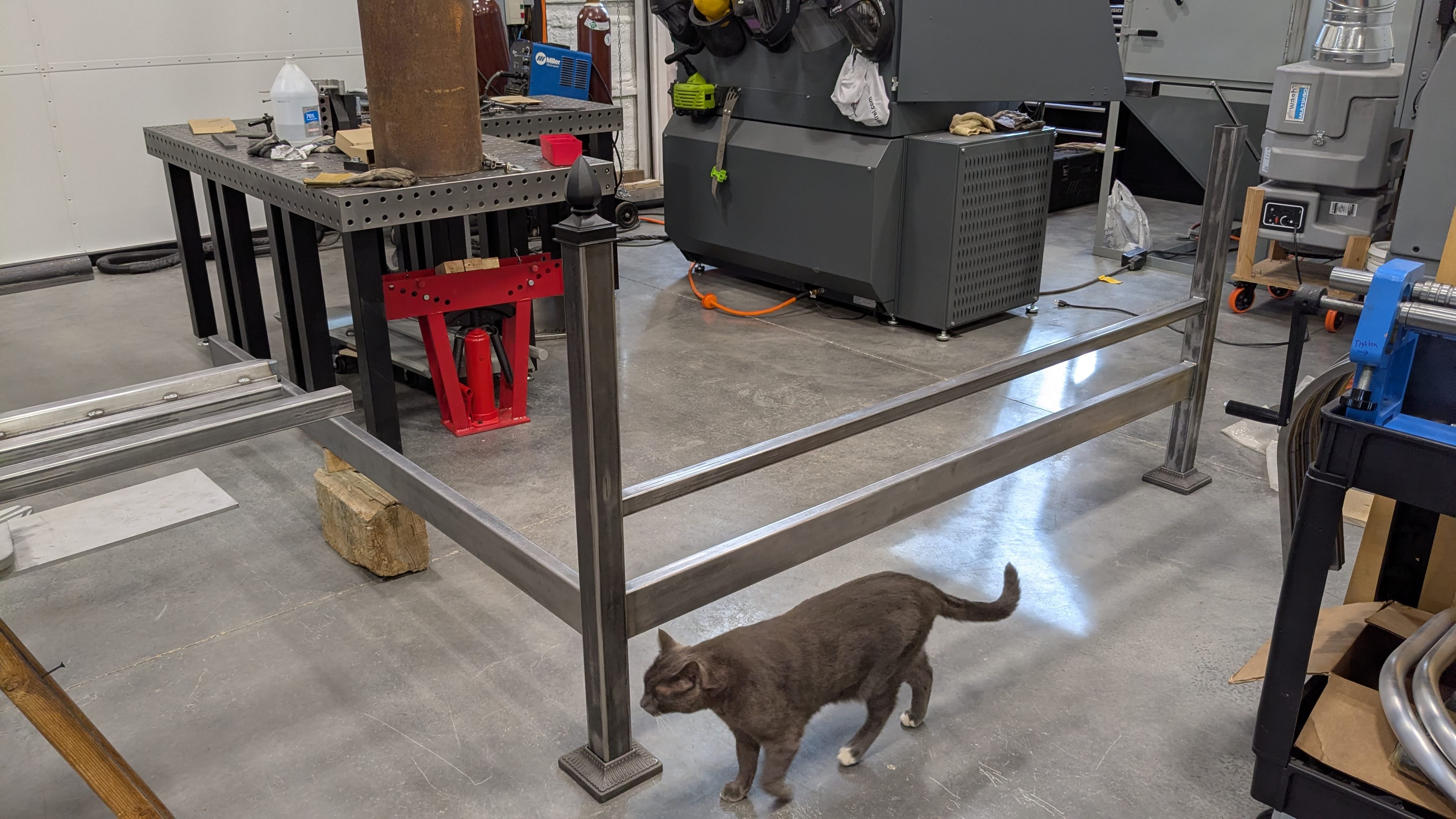

The bandsaw in the shed wasn’t set up yet, so we had to shuffle the long tubes around in the shop. Sam cut all the components.

I had very little involvement in the project besides cleaning the tubes (which isn’t a trivial task). Sam had the bed frame welded in no time. I think the wooden bed would have taken at least 10x as long.

We took everything to the painter for a smooth black finish. The truck was missing its tailgate at the time (a semi backed into it while it was parked…), so the headboard and footboard had to stand up in the truck bed.

We made it to and from the painter without incident. Assembling the bed was quick and easy thanks to Sam’s design. There are four main parts – the headboard, footboard, and two side rails. He machined pockets in the ends of the 1″x4″ side rails for the fasteners. You can access the fasteners from the inside, and they are concealed from the outside.

Sam’s biggest concerns were squeakiness and stiffness. To solve this, we used metal slats instead of wood.

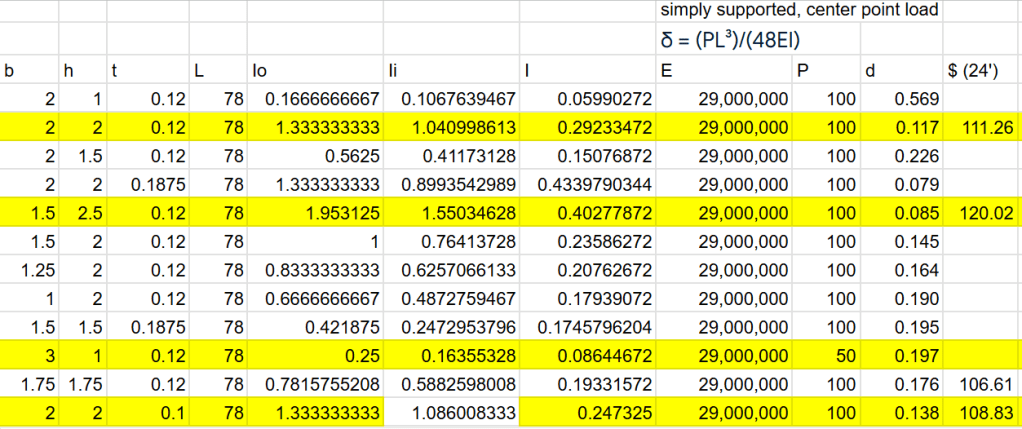

I made this great spreadsheet to determine the optimal size slats to support the mattress.

Then I was informed that the tubes only come in certain sizes and thicknesses, which narrowed down our options. We chose 1″x3″ tubes, spaced about 9 inches apart. The slats sit freely on the rails, but we put adhesive felt under them to minimize sliding.

To cap things off, I selected finials. The finial catalog is surprisingly longer than a Cheesecake factory menu. We didn’t want to bump into a medieval weapon in the dark, so that eliminated half of the selection.

I chose these cool ones from the pineapple category. They fit right over the posts (after some serious pounding), so Sam didn’t need to weld them.

We needed big feet for our big bed, so we ordered these to slip over the 2.5″ tubes.

It may be the world’s heaviest bed, but it looks great! It’s the perfect height to get in and out of. We also added a little extra space between the mattress and the frame so your fingers don’t get crushed trying to put a fitted sheet on. It was a dream to make, and it’s a dream to make.

Ta-da! Ignore the bedding. I’m not done decorating the bedroom, and there is currently a sea of pillows in our bed.