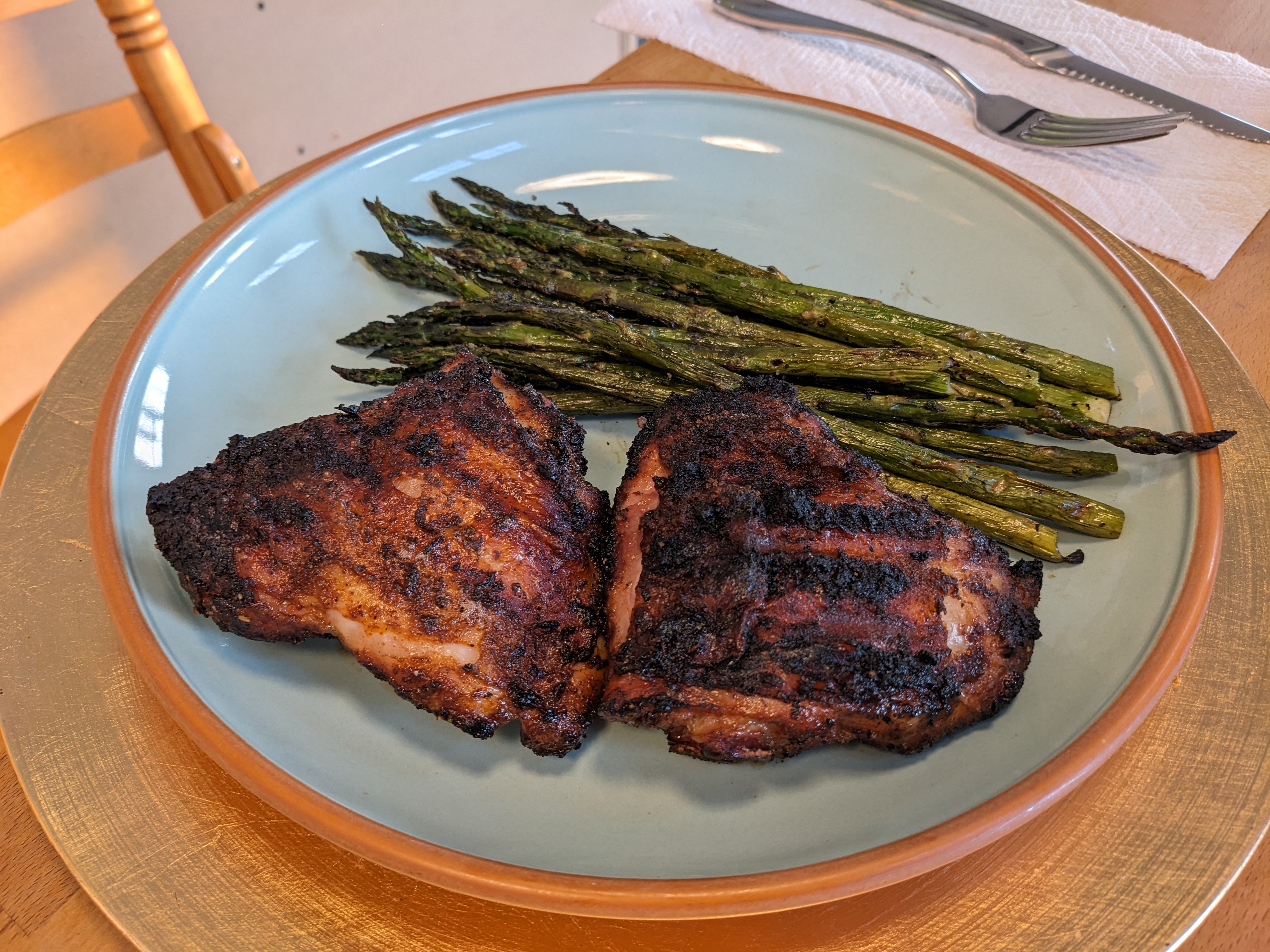

We’ve had our typical dry, sunny summer, but unlike some previous years, we haven’t had too many smokey days. In fact, most of the smoke in the air was from our new smoker!

This pellet smoker is great. We have ribs and chicken thighs dialed in.

Although we didn’t have many wildfires in the area, we were still subjected to the blistering heat. For the first month of summer, we managed to keep the building cool by opening our windows at night and relying on our insulation during the day. However, things started to heat up indoors once we got into triple digit days and warmer nights. When Buster started seeking out cooler places to nap, we realized it was time to focus on getting the heat pump running so we could turn on the AC.

First, we had to run a water line from the mechanical room to the heat pump. The line barely fit through the 4″ conduit with its thick foam insulation, and it took extra strength to overcome the friction. Luckily Jackson was here to help pull the line!

Sam and Jackson got it through!

Then our hydronic crew, Terry, Allan, and Buster, finished hooking up the plumbing to the individual components- the heat pump, buffer tank, expansion tank, and fan coils.

For you geeks, the buffer tank holds the cooled (or heated) water and remains full- ready to distribute the hot or cold water to the floor tubes or the fan coils. The expansion tank is the small tank (see above) that contains a diaphragm allowing for volume changes when switching between cooling and heating.

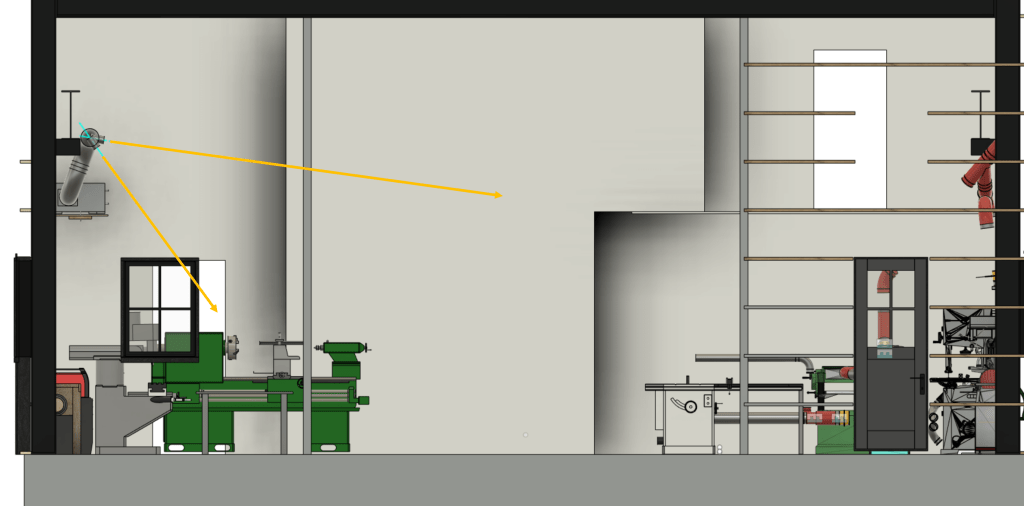

We have one fan coil in the living room and smaller ones in the bedroom and office. We were going to put another high-wall unit in the shop, similar to the living room one…

But we did something entirely different. For starters, we got a more powerful unit. Meet the “air handler”.

Sam and I built a nice pine shelf for it to sit on.

Then we used our brains to put it up.

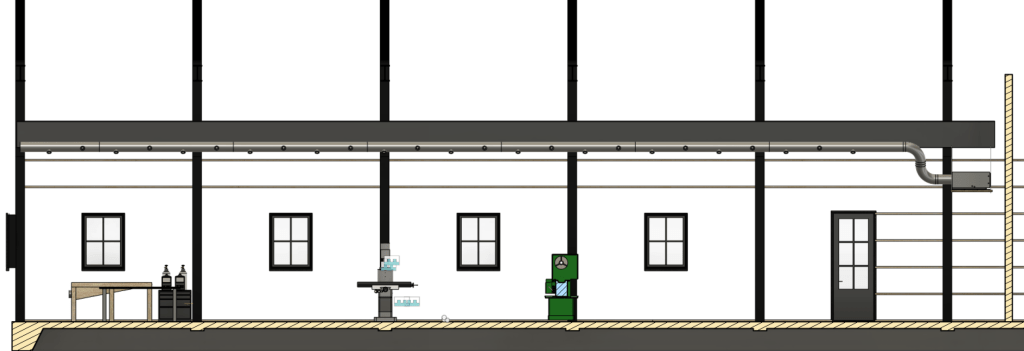

The second big design change was adding a duct with outlets along the entire length of the crane beam. The duct should distribute the air significantly better than a fan coil (where it comes out of a single source.)

Sam’s initial design was an outlet pattern alternating between 2 positions. I was concerned about the air distribution, but Sam thought it would be a pain to drill a more complicated hole pattern. (The arrows in the image below show the airflow direction.)

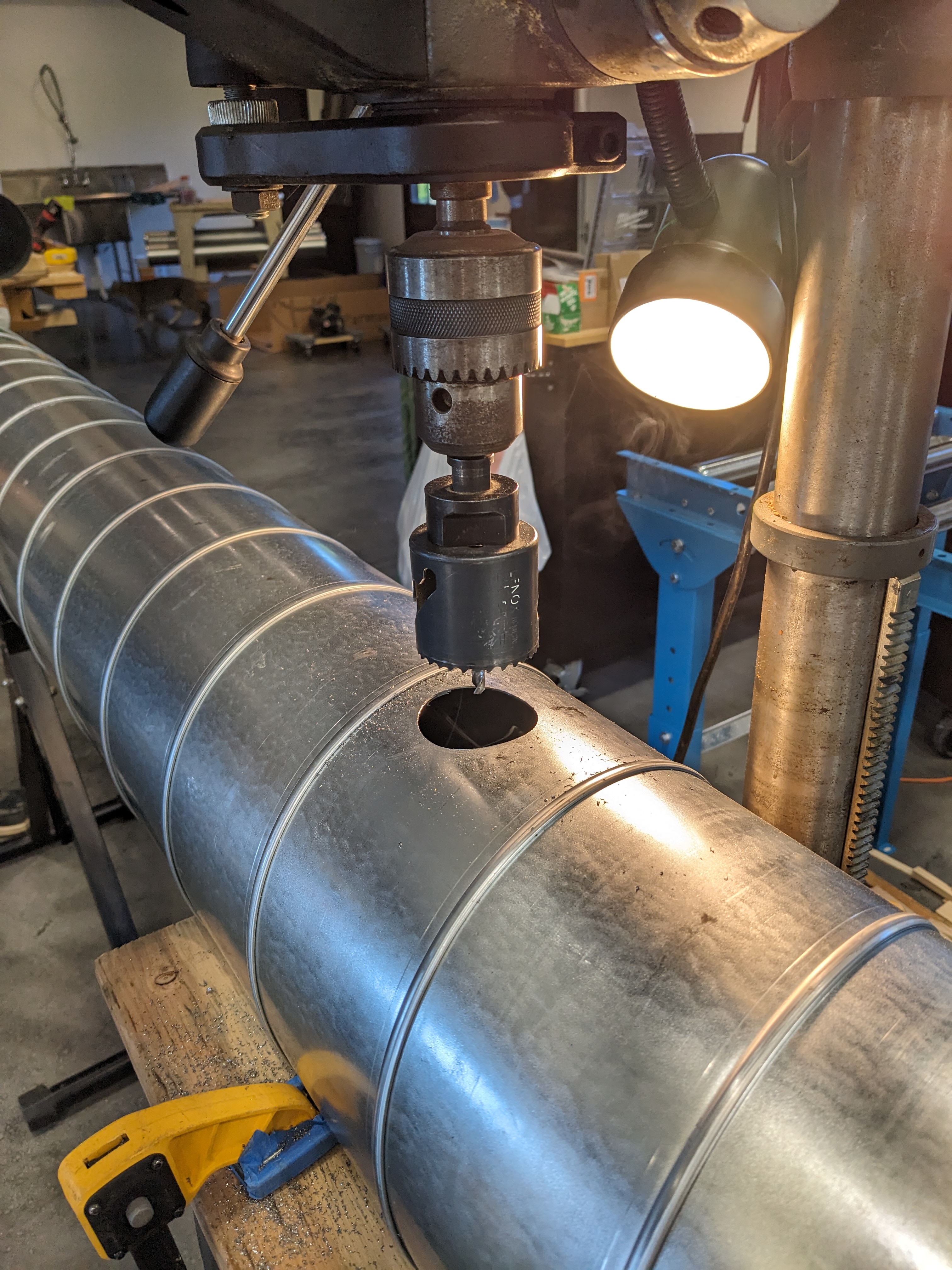

After some coaxing, Sam agreed on a pattern with 4 different hole positions. This should result in a more uniform air distribution. Sam of course found a simple way to clock the hole locations using a laser and basic geometry.

Then he drilled the complicated pattern with no problems.

Next, we cleaned the sharp metal debris from the ducts. We didn’t want metal shards raining down when we turn on the AC for the first time. Sam came up with the pillow method. It’s similar to the cat toy thing that is used to clean gun barrels. This was probably my favorite part of this project.

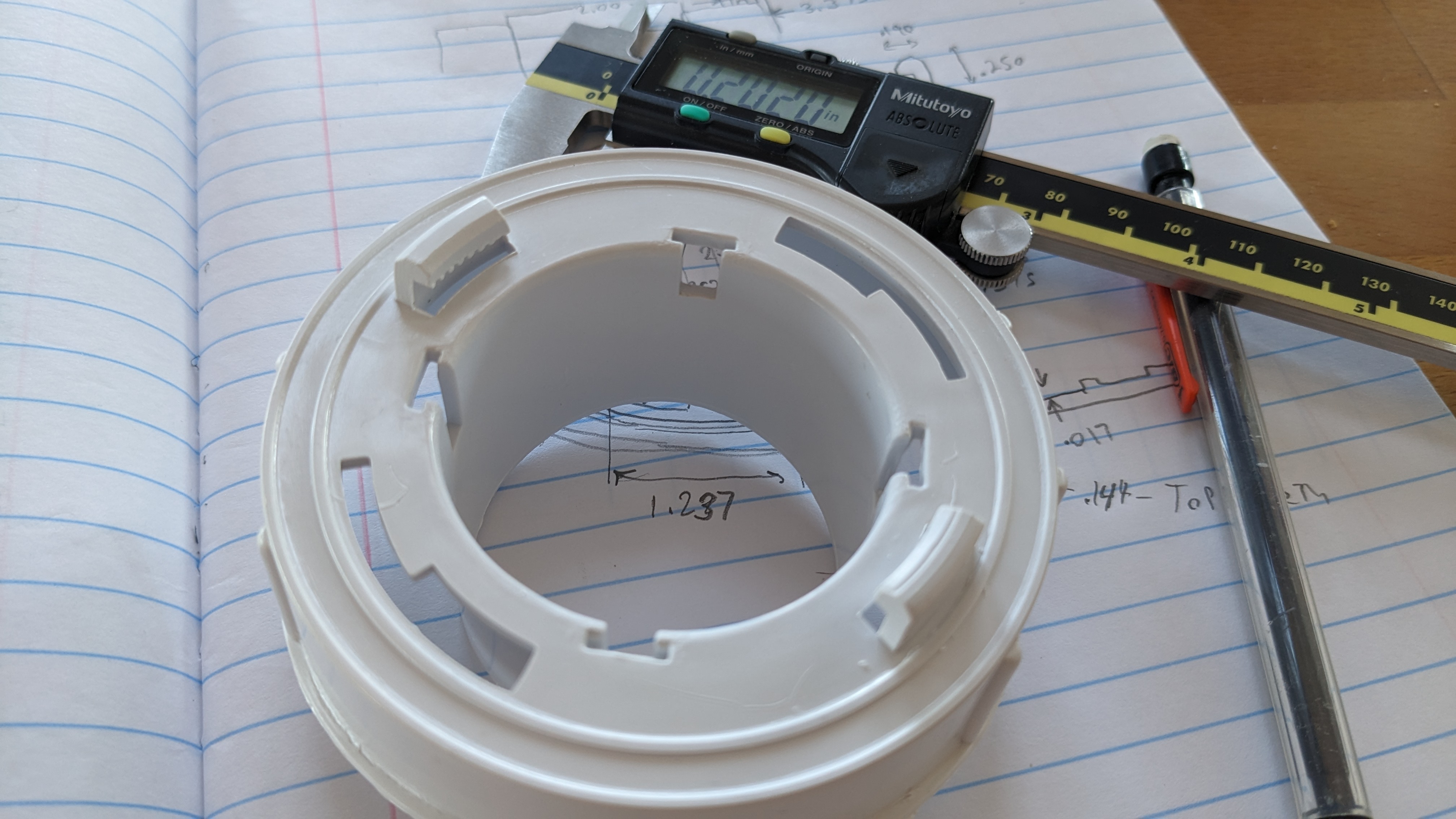

The outlet nozzles snapped in easily. It’s somewhat unconventional to use them without hoses, so we were hoping they wouldn’t whistle or vibrate too much.

Assembly time.

Sam installed the ducting with some help from Allan. This type of duct came in 10 ft long segments that interlock by shoving them together.

Then Allan hooked up the air handler. Unlike our fan coils which are controlled with remotes, the air handler is tied into a thermostat. It has the option of running on high, low, and fan only. (We’re going to cover the wires and pipes along the wall with a pine board.)

He also pumped glycol into the whole system via the buffer tank. We bought 50 gallons of glycol to achieve a 40% glycol-water mix to prevent freezing. And we happened to have a 20% off coupon to an online store that sells glycol! After a few spills, the buffer tank was filled with 40 gallons of glycol. It didn’t seem possible to get the last little bit in, and 40 gallons seemed good enough.

Time to turn on the AC!

It’s surprisingly not too loud or annoying. You hardly notice it’s running on the low setting, and more importantly, it works! It cools the entire shop fairly quickly.

Now the cats can bask in the sun, even when it’s 100 degrees outside.

And for the last smoke related activity- Sam and I attended a local workshop where we learned about prescribed fire. It was interesting to learn how 100 years of fire suppression and poor logging practices became the major contributors to all these devastating wildfires (not climate change). Prescribed or “controlled” burning is a safe and effective way to reintroduce fire into the environment, creating healthier and more fire resilient forests. We also learned cool things about fire and smoke behavior before entering the woods to set 25 acres on fire. (Notice the smoke isn’t crossing the road in the photo below!)

It was a great experience but sure was nice to come back to a cool house after that.

nerd in me is perking up: curious, how’d you pick 40% for the glycol?

LikeLike

the pillow move reminds me of dragging techs out of the transfer tube with a rope around their ankles

LikeLike